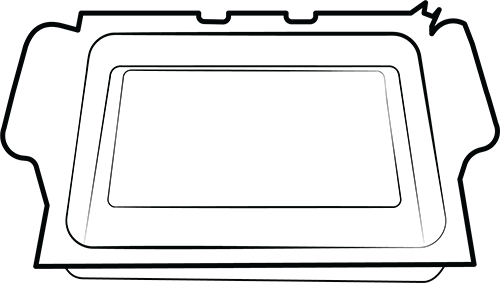

Clean Material Tray

![]() CAUTION

CAUTION

Risk of injury: Always wear nitrile gloves when handling items that come into contact with uncured resin.

NOTICE

Always remove the platform before taking the material tray out of the printer. Failure to do so can result in material dripping down into or onto the printer causing failed builds and damaged equipment.

NOTICE

Always clean the material tray each time you need to change the material for printing parts on the printer.

Do not pour material from your material tray into the bottle it came from. This can potentially contaminate the whole bottle of material and ruin it.

NOTICE

Never use chemicals inside the material tray. This will contaminate and ruin any material you put into the material tray.

Time needed: Approximately five minutes

Maintenance frequency: Weekly

The material tray is a consumable with an approximate lifespan of up to 150 prints. Order a new material tray before the current tray expires or becomes damaged.

The Pre-Stretched Assembly (PSA) is located inside the material chamber and is comprised of a film and a frame.

- Check the film at the bottom of the material tray whenever the material is removed.

- Look for pinholes, punctures, ripples, and other signs of stress. A slightly cloudy film is normal and will not affect the print quality.

- Use Manual Debris Removal to remove cured material from the surface of the film assembly at the end of a print, or access it by navigating to Home > Settings > Manual Debris Removal on the printer.

- Once the exposure time is set on the Manual Debris Removal page, select Expose.

→ The projector will expose the full printing area to light for the set exposure duration. - Use the rubber spatula to gently remove the cured material from the surface of the film assembly.

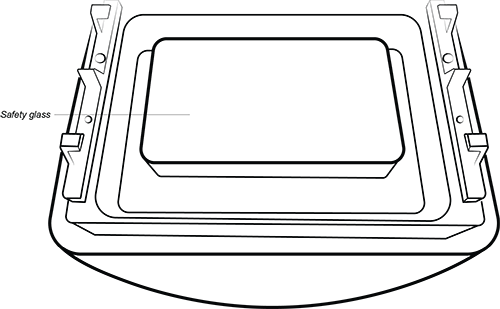

Clean Safety Glass

Time needed: Approximately five minutes

Maintenance frequency: Weekly

In case something does not stick to the platform or falls down from the supports, it is necessary to inspect the safety glass right away and clean it.

-

Spray a small amount of alcohol directly on the paper towel.

Important: Do not spray alcohol anywhere in the printer or directly on the glass panel. -

Wipe down the top surface of the safety glass.

-

Take the microfiber cloth and spray a small amount of lens or window cleaner on it.

-

Wipe down the top surface of the safety glass with the cloth. Make sure that it is dry in the end.

Note: Make sure that the safety glass is absolutely clean so that there is no smudging, streaking, or material spots anywhere on it.Important: If the glass cracks or is badly scratched please contact Customer Support.